Bring Proactive Will Save You Money In The Long Run

Contact WBEYour electrical system isn’t just a utility—it’s the heartbeat of your business operations. But without proactive inspection, testing, and servicing, even the most advanced infrastructure can fail, creating safety hazards, unplanned downtime, and insurance claim disputes.

Electrical Maintenance Shutdowns aren’t just a “nice-to-have”—in many industries, they’re essential for regulatory compliance and insurance coverage.

What Is an Electrical Maintenance Shutdown?

An Electrical Maintenance Shutdown is a planned, controlled outage during which certified technicians perform inspections, testing, upgrades, and repairs on your electrical infrastructure.

Unlike emergency outages, these are strategically scheduled to minimize operational disruption while maximizing equipment reliability, safety, and compliance.

NFPA 70E: The Compliance Backbone

NFPA 70E is the nationally recognized standard for electrical safety in the workplace. It outlines how to protect employees from electrical hazards, including shock, electrocution, arc flash, and arc blast.

While many people associate NFPA 70E strictly with safety procedures and PPE, it also directly addresses preventive maintenance—because failing to maintain equipment increases the risk of dangerous incidents.

A core principle of NFPA 70E is that electrical equipment must be maintained in accordance with manufacturers’ instructions and industry standards—and that means regular, documented inspections and testing.

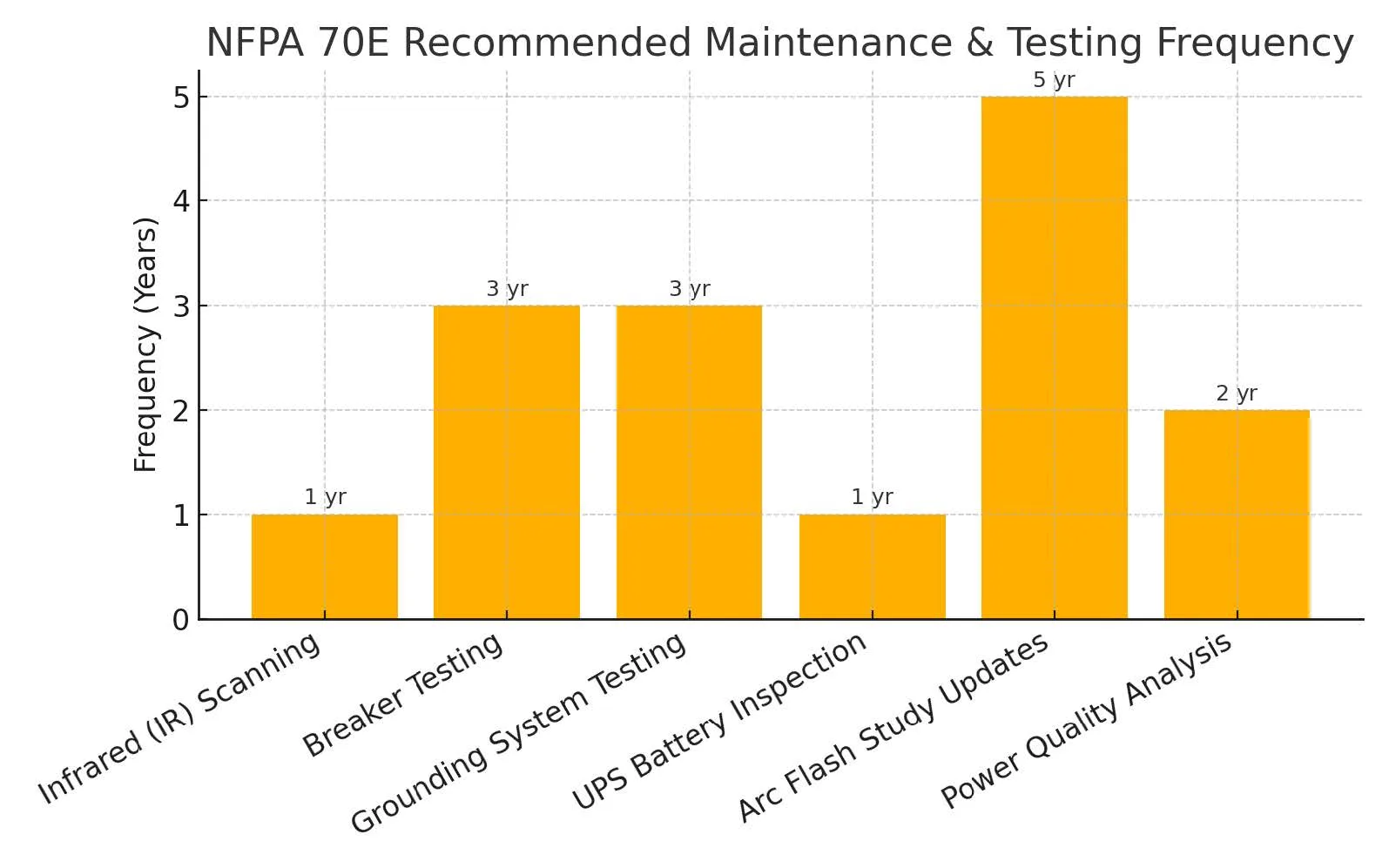

NFPA 70E Recommended Maintenance & Testing Frequency

Below is a visual overview of common NFPA 70E-related maintenance intervals:

Key Maintenance Activities & Frequency

- Infrared (IR) Scanning – Every 1 year to detect hot spots before failure.

- Breaker Testing – Every 3 years to ensure proper trip functions.

- Grounding System Testing – Every 3 years to maintain safe fault clearing.

- UPS Battery Inspection – Annually, to prevent mission-critical power loss.

- Arc Flash Study Updates – Every 5 years or after major system changes.

- Power Quality Analysis – Every 2 years to detect voltage sags, harmonics, and transients.

By following these intervals, businesses not only meet NFPA 70E requirements but also strengthen compliance with NFPA 70B (now mandatory) and improve their position with insurers.

Why Insurance Companies Care

More insurers now require documented proof of preventive electrical maintenance to:

- Qualify for coverage

- Maintain favorable premiums

- Reduce claim risk

Without proof, a claim from an electrical fire or outage could be reduced—or even denied—if the insurer finds that the system was not properly maintained.

What WBE Delivers During a Shutdown

Power & Distribution

- Emergency Generators

- Service Upgrades

- UPS Systems

- Surge Protection

- Medium Voltage (up to 35kV)

- Grounding Systems

- Temporary Wiring

- Underground Utilities

Testing & Maintenance

- Breaker Testing

- Infrared Scanning & Analysis

- Power Quality Analysis

- Preventive Maintenance

- Critical Outage Work & Coordination

Controls & Equipment

- VFDs & Motor Controls

- Process Control

- Control Wiring

- Dimming Systems

- Lighting Controls

- Lighting Retrofits

- Cubicle/Furniture Wiring

Specialty & Commercial

- Tenant Finish-Out

- Parking Lot & Security Lighting

- Emergency Management Controls

- Special Events

The Payoff of Going Proactive

A well-planned Electrical Maintenance Shutdown provides:

- Employee and customer safety

- Fewer unplanned outages

- Extended equipment life

- Improved energy efficiency

- Preserved insurance coverage

Partner With WBE — A Proven Expert

At WBE, we combine NFPA 70E compliance expertise with deep field experience to deliver safe, efficient, and tailored shutdowns. Whether you operate in commercial, industrial, or mission-critical environments, we keep your systems reliable, compliant, and ready for whatever’s next.

Don’t wait for a costly failure—or an insurance denial—to take action.

Schedule your Electrical Maintenance Shutdown today.